The Foresight Practitioner’s Conference held last week in on the campus of Ohio State University highlighted business gains in forecasting and the bottom line from integration across the supply chain.

Officially, the title of the Conference was “From S&OP to Demand-Supply Integration: Collaboration Across the Supply Chain.”

S&OP is an important practice in many businesses right now – Sales and Operations Planning. By itself it signifies business integration, but several speakers – starting off with Pete Alle of Oberweiss Dairy – emphasized the importance of linking the S&OP manager with the General Manager directly, and of his sponsorship and support.

Luke Busby described revitalization of an S&OP process for Steris – a medical technology leader focusing on infection prevention, contamination control, surgical and critical care technologies. Problems encountered were that the old process was spreadsheet driven, used minimal analytics, led to finger pointing – “Your numbers!”, was not comprehensive – not all products and plants included, and embodied divergent goals.

Busby had good things to say about software called Smoothie from Demand Works in facilitating the new Steris process. Busby described benefits from the new implementation at a high level of detail, including the ability, for example, to drill down and segment the welter of SKU’s in the company product lines.

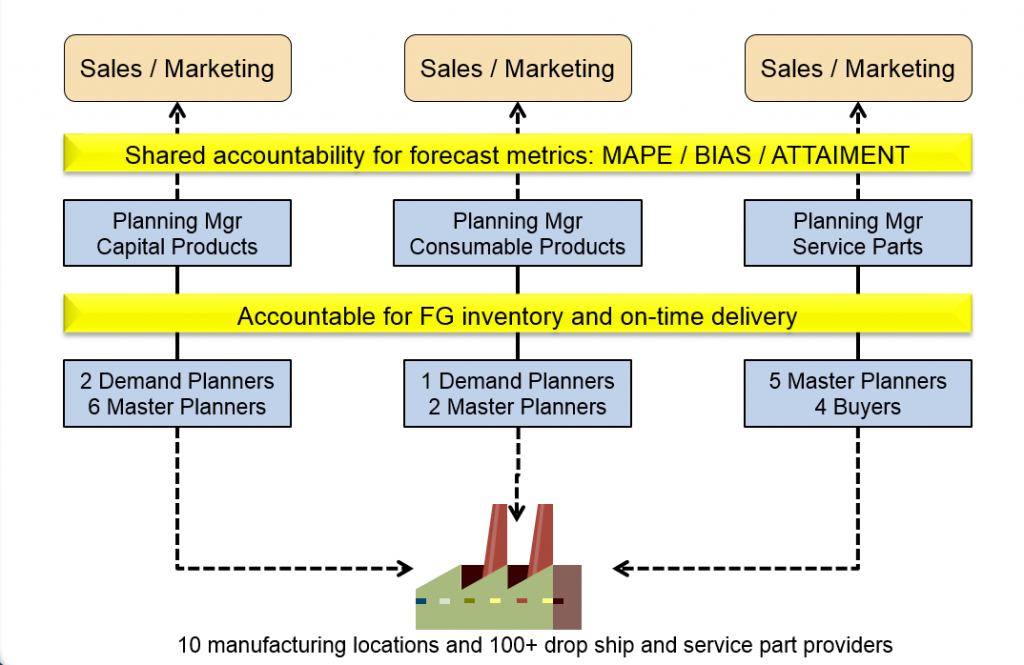

I found the talk especially interesting because of its attention to organization detail, such as shown in the following slide.

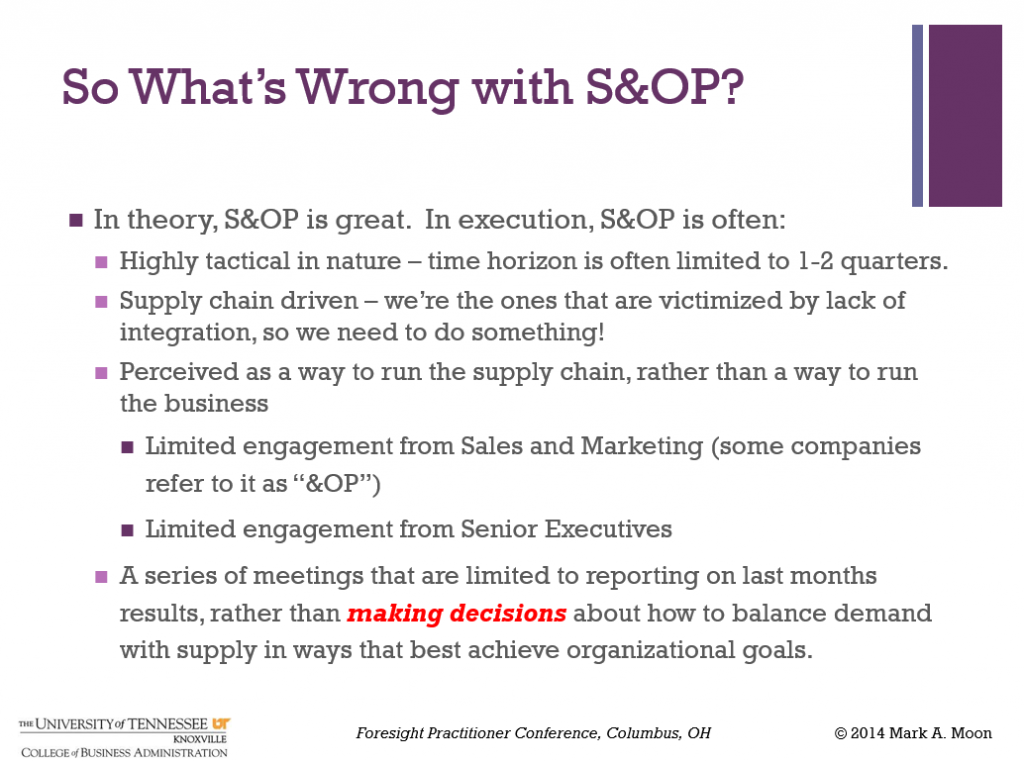

But this was more than an S&OP Conference, as underlined by Dr. Mark A. Moon’s presentation From S&OP to True Business Integration. Moon, Head, Department of Marketing and Supply Chain Management, University of Tennessee, Knoxville, started his talk with the following telling slide –

Glen Lewis of the University of California at Davis and formerly a Del Monte Director spoke on a wider integration of S&OP with Green Energy practices, focusing mainly on time management of peak electric power demands.

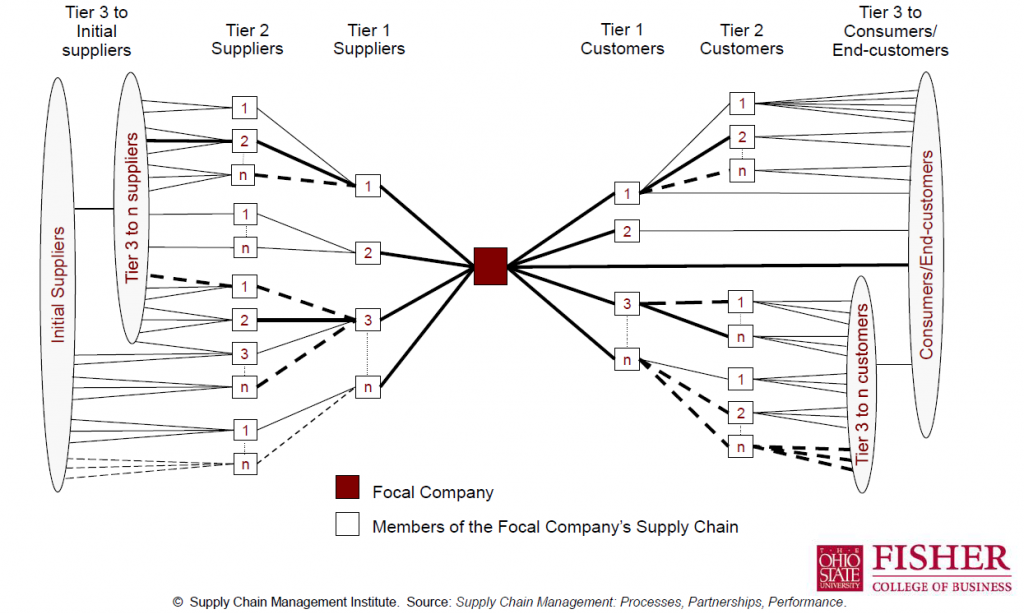

Thomas Goldsby, Professor of Logistics Fisher College of Business who introduced the concept of the supply web (shown below), and co-presented with Alicia Hammersmith, GM for Materials, General Electric Aviation. I finally learned what 3D printing was.

Probably the most amazing part of the Conference for me was the Beer Game, led by James Hill, Associate Professor of Management Sciences at The Ohio State University Fisher College of Business. Several tables were set up in a big auditorium in the Business School, each with a layout of production, product warehousing, distributor warehouses, and retail outlets. These four positions were staffed by Conference attendees, many expert in supply chain management.

The objective was to minimize inventory costs, where shortfalls earned a double penalty. No communication was permitted along these fictive supply chains for beer. Demand was unknown at retail, but when discovered resulted in orders being passed back along the chain, where lags were introduced in provisioning. The upshot was that every table created the famous “bullwhip effect” of intensifying volatility of inventory back along the supply chain.

Bottom line was that if you want to become a hero in an organization short-term, find a way to reduce inventory, since that results in immediate increases in cash flow.

All very interesting. Where does forecasting fit into this? Good question, and that was discussed in open sessions.

A common observation was that relying on the field sales teams to provide estimates of future orders can lead to bias.